The

Powder Coating Heater is an indispensable component in the powder coating process. It plays a vital role in transforming the powder applied to a surface into a durable, long - lasting finish.

At its core, the

Powder Coating Heater functions by providing the necessary heat to cure the powder. Powder coatings are typically thermosetting, meaning they undergo a chemical change when heated. The heater raises the temperature of the powder - coated object to a specific range where the powder particles melt, flow together, and form cross - links. This results in a hard, protective layer.

Most heaters operate on either electric or gas - fired principles. Electric heaters use resistance elements that generate heat when an electric current passes through them. Gas - fired heaters, on the other hand, burn gas to produce heat. The choice between the two often depends on factors like energy costs, availability, and the specific requirements of the powder coating operation.

A typical

Powder Coating Heater consists of several key components. The heating element, whether it's an electric coil or a gas - burning burner, is the heart of the system. It's responsible for generating the heat. Alongside the heating element is a temperature control mechanism. This can include thermostats and sensors that monitor the temperature and adjust the heat output accordingly.

The heater is also often integrated with a ventilation system. This is crucial for several reasons. Firstly, it helps in distributing the heat evenly throughout the oven or the workspace where the powder - coated item is being cured. Secondly, it removes any fumes or volatile compounds that may be released during the curing process.

Powder Coating Heaters are used across a wide range of industries. In the automotive industry, they are used to cure the powder coatings on car parts such as the body, wheels, and engine components. This provides protection against corrosion and gives the car a sleek, attractive finish. In the furniture industry, heaters are used to cure powder coatings on wooden and metal furniture, enhancing their durability and appearance. They are also used in the manufacturing of home appliances, where they ensure a long - lasting and scratch - resistant coating.

FQA

Q: How do I choose between an electric and a gas - fired Powder Coating Heater?

A: Consider your energy costs. If electricity is more cost - effective in your area, an electric heater may be a better choice. Also, think about the availability of gas. If gas supply is unreliable, an electric heater is more suitable. Additionally, electric heaters offer more precise temperature control, while gas - fired heaters can sometimes provide more rapid heating.

Q: Can I use a Powder Coating Heater for different types of powder coatings?

A: Yes, but you need to ensure that the heater can reach and maintain the specific curing temperature required for each type of powder. Different powder coatings, such as epoxy, polyester, or acrylic, have different curing temperature requirements.

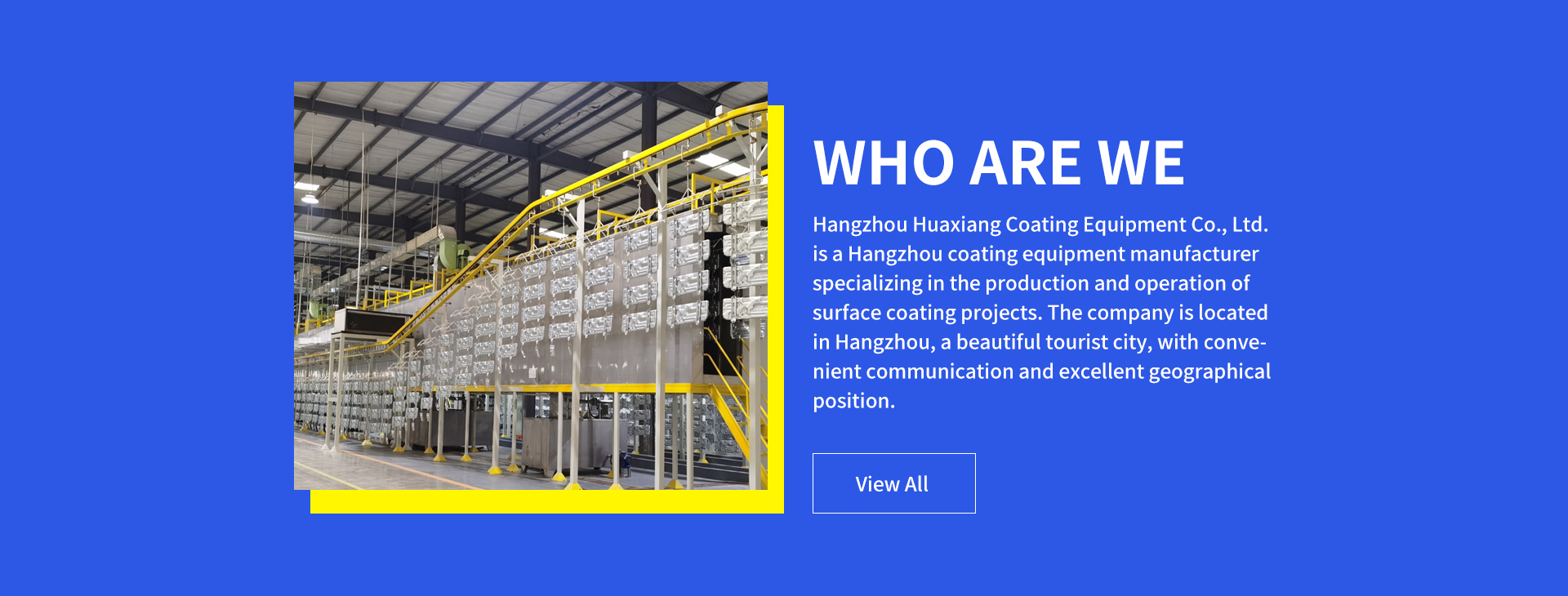

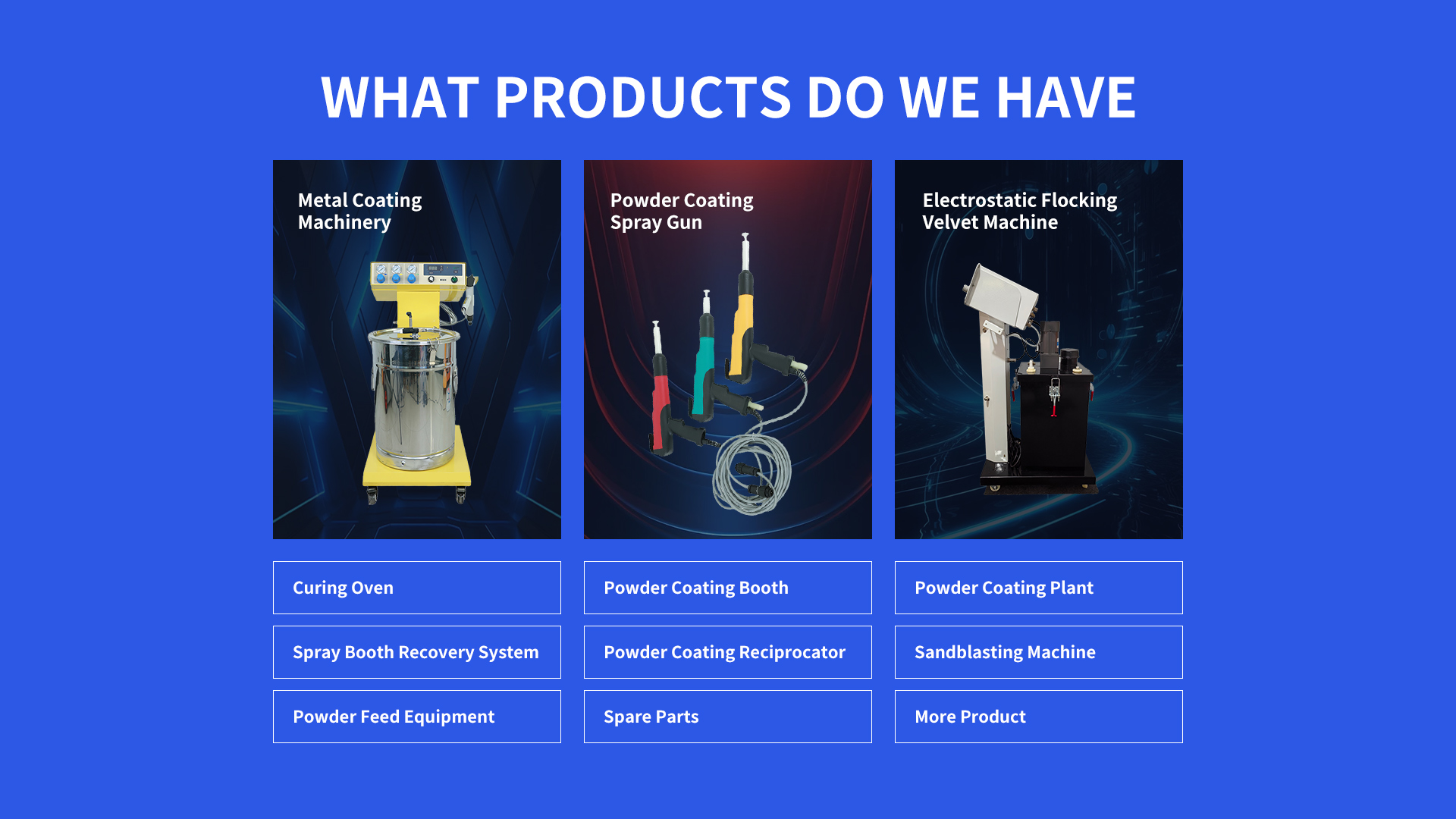

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com